cascoda-sdk-pages

Battery Monitoring

Devboard Jumper Configurations

To use the battery monitoring functions, jumpers U14/17, U23, and U27 should be populated. Each pin on jumper U14/17 correspond to different functionality respectively and can be used individually, not all of them have to be populated at the same time. The description of each pin on jumper U14/17 are as follows:

| Pin Name | Signal | Description |

|---|---|---|

| INT | USB_PRESENT | USB (or external) +5V is connected |

| RST | VOLTS_TEST | Battery Voltage Measurement: Control |

| PWM | VOLTS | Battery Voltage Measurement: Battery Voltage to ADC for Measurement |

| AN | CHARGE_STAT | Battery Charging Status (Charging/Not Charging) |

NOTE: VOLTS_TEST and VOLTS both need to be populated at the same time if the battery voltage is to be measured.

Methodology for Battery Percentage Calculation

If VOLTS_TEST and VOLTS are enabled, the battery voltage could be measured and converted to its corresponding value in percentage (%) by using the battery’s charge/discharge curve. Note that every type of battery will have its own charge/discharge curve. The battery types currently implemented are the RCR123A 3.7V Rechargeable Lithium-Ion Battery and the CR123A 3V Non-Rechargeable Lithium Battery.

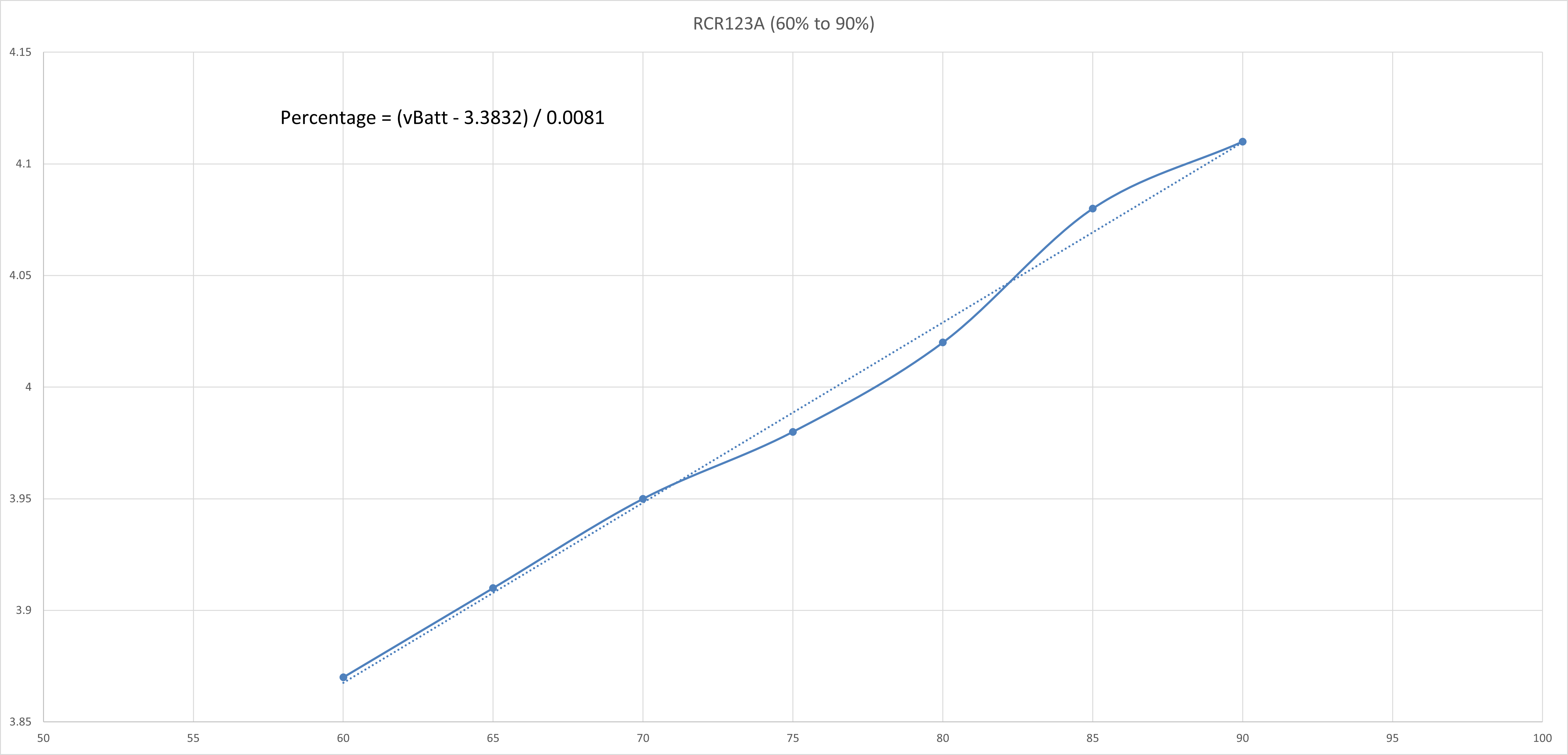

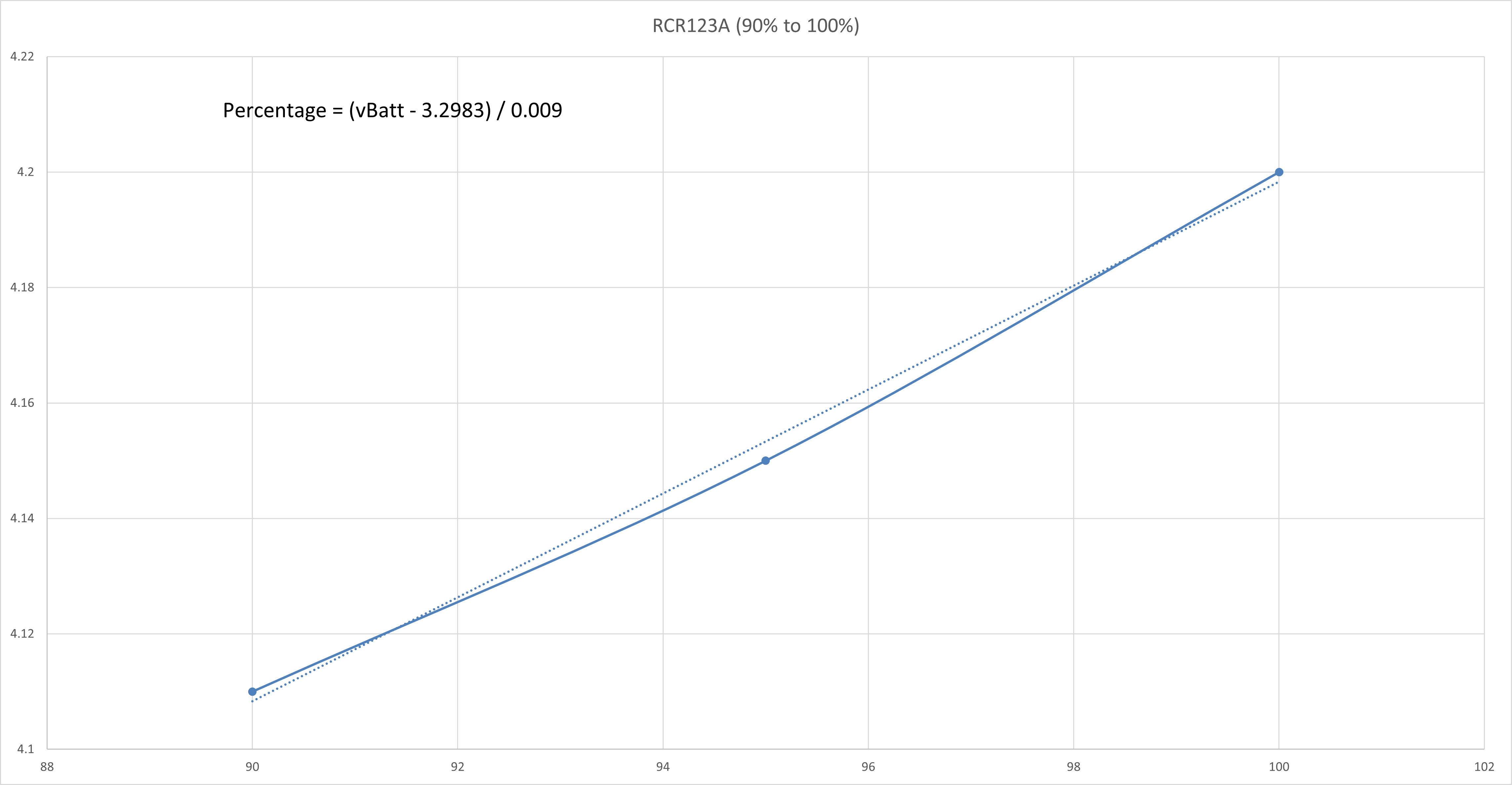

RCR123A 3.7V Rechargeable Lithium-Ion Battery

The typical 3.7V Lithium-Ion Battery voltage vs capacity table is shown as follows:

| Capacity | Voltage |

|---|---|

| 100 | 4.20 |

| 95 | 4.15 |

| 90 | 4.11 |

| 85 | 4.08 |

| 80 | 4.02 |

| 75 | 3.98 |

| 70 | 3.95 |

| 65 | 3.91 |

| 60 | 3.87 |

| 55 | 3.85 |

| 50 | 3.84 |

| 45 | 3.82 |

| 40 | 3.80 |

| 35 | 3.79 |

| 30 | 3.77 |

| 25 | 3.75 |

| 20 | 3.73 |

| 15 | 3.71 |

| 10 | 3.69 |

| 5 | 3.61 |

| 0 | 3.27 |

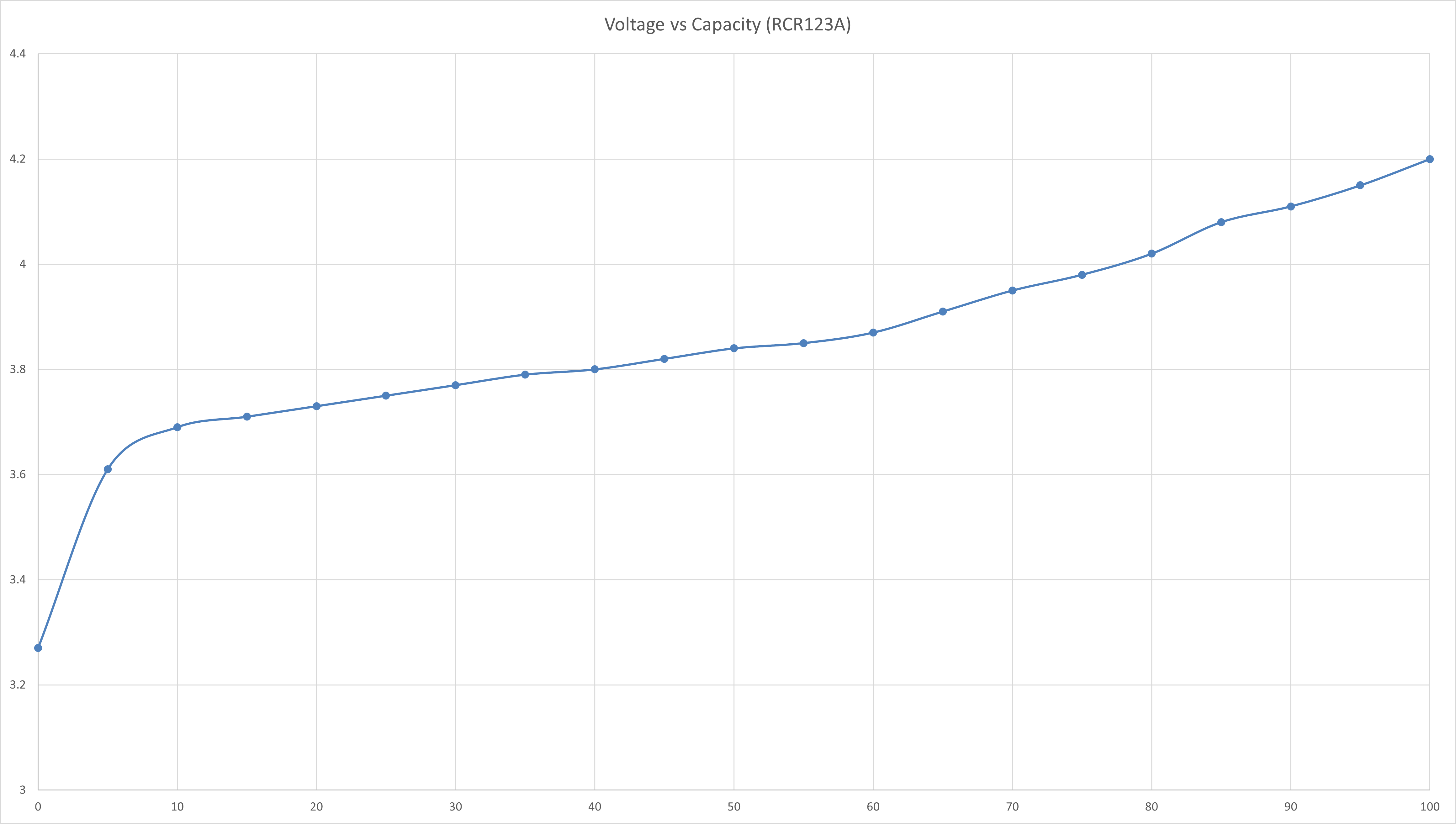

The voltage vs capacity graph is then plotted using Excel and is shown as follows:

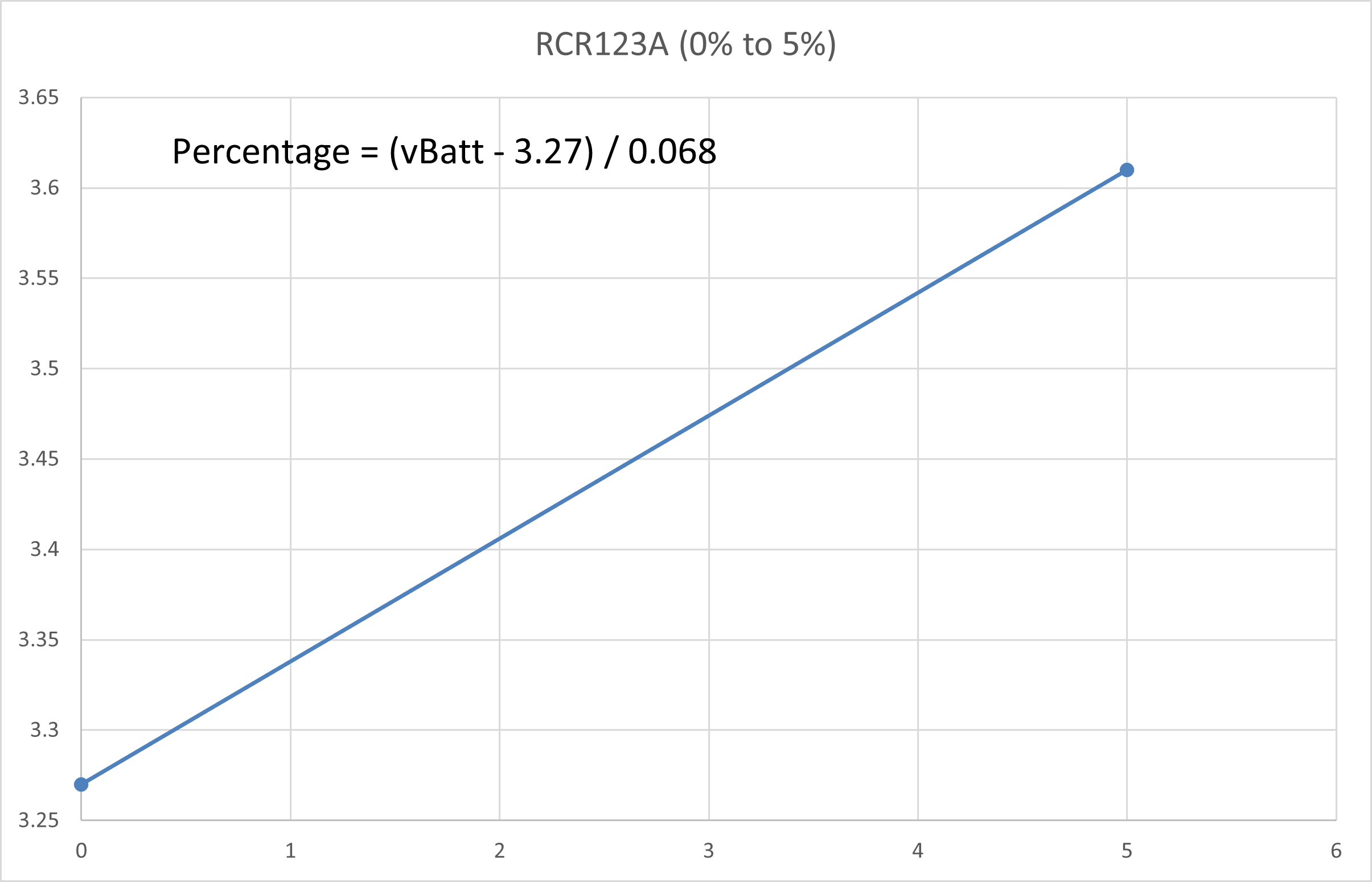

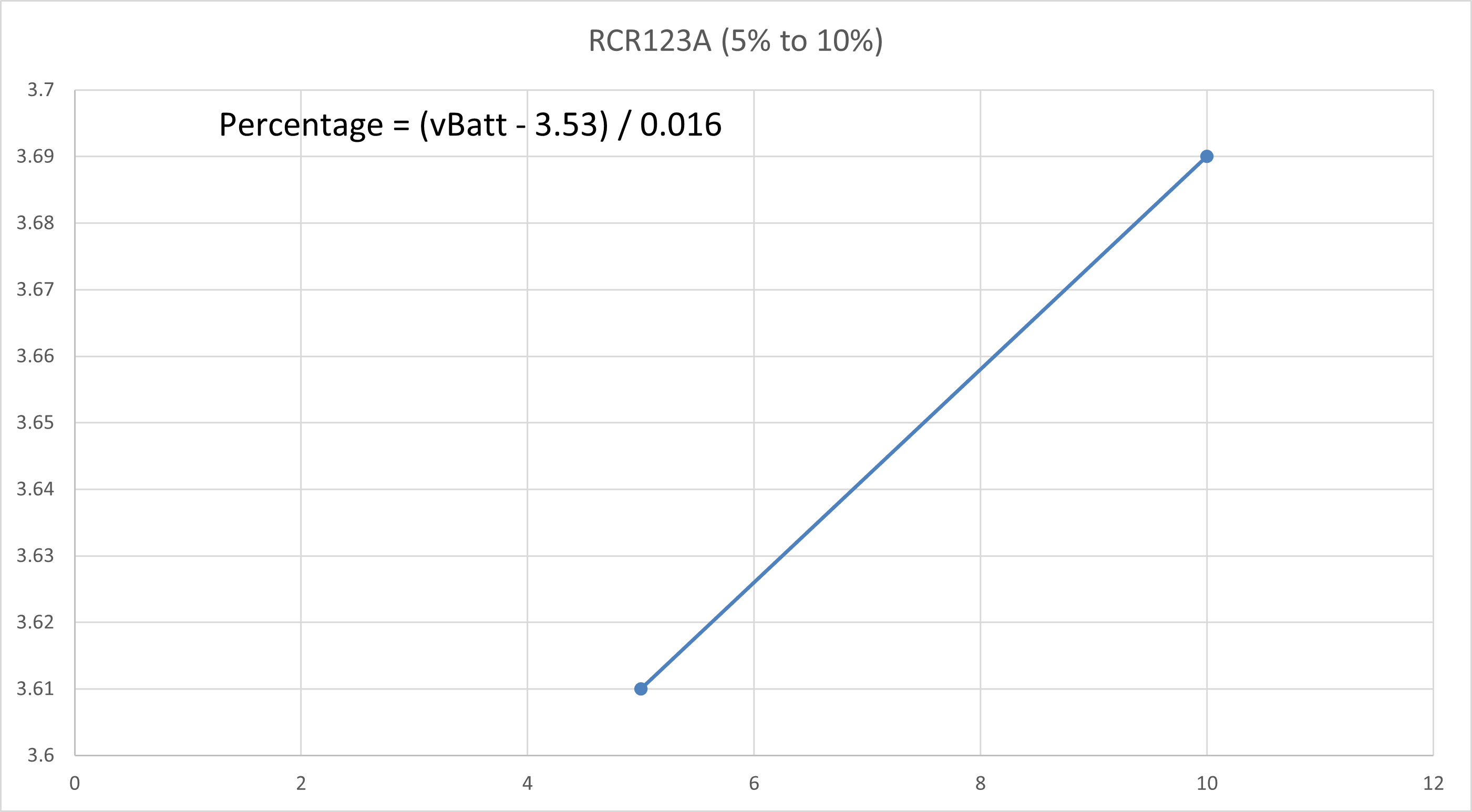

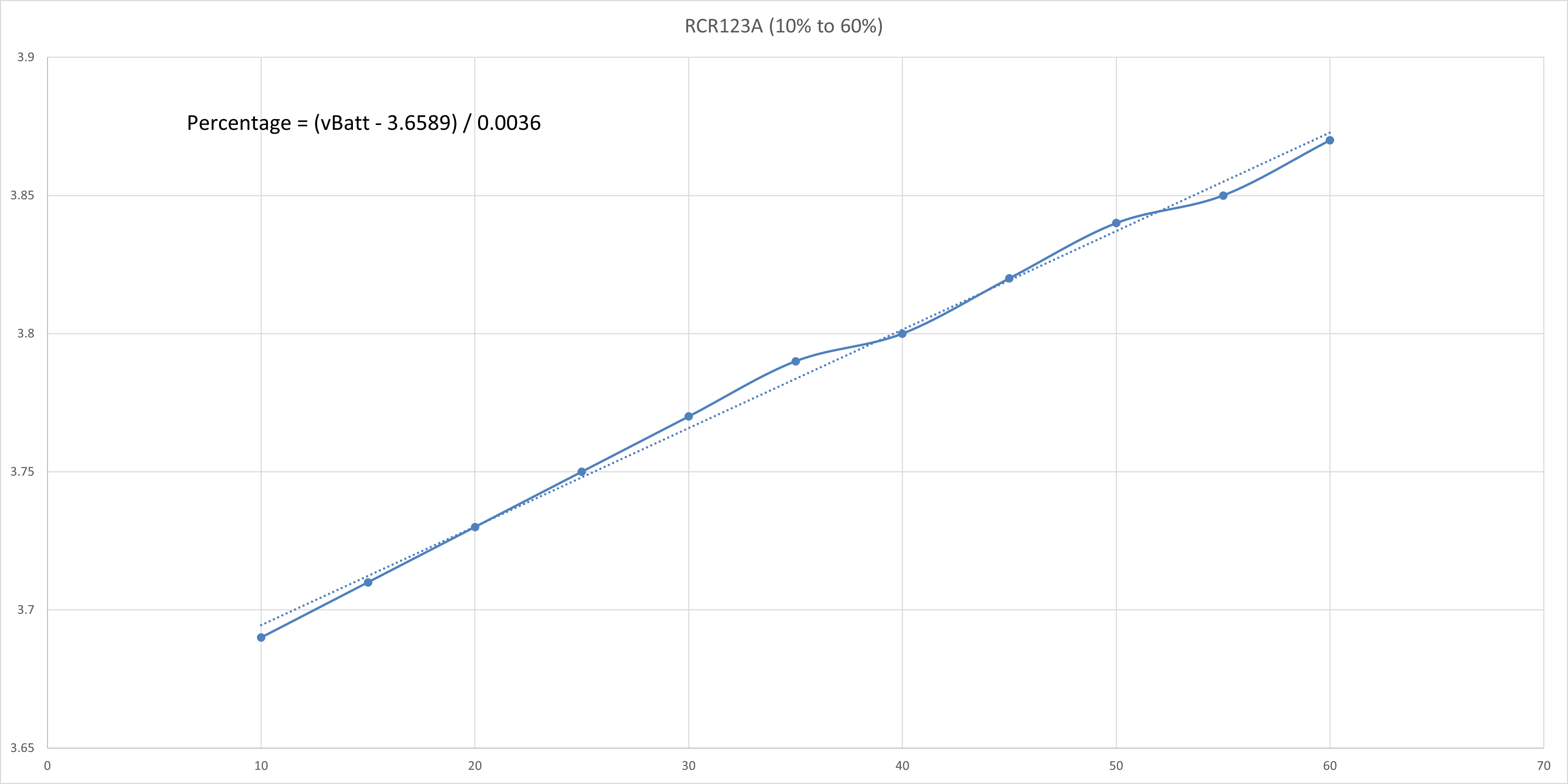

The curve is then split into a few regions where each region could be reasonably linearised with a line of best fit. The straight line equation of each linearised region is obtained and the battery percentage value could be calculated correspondingly.

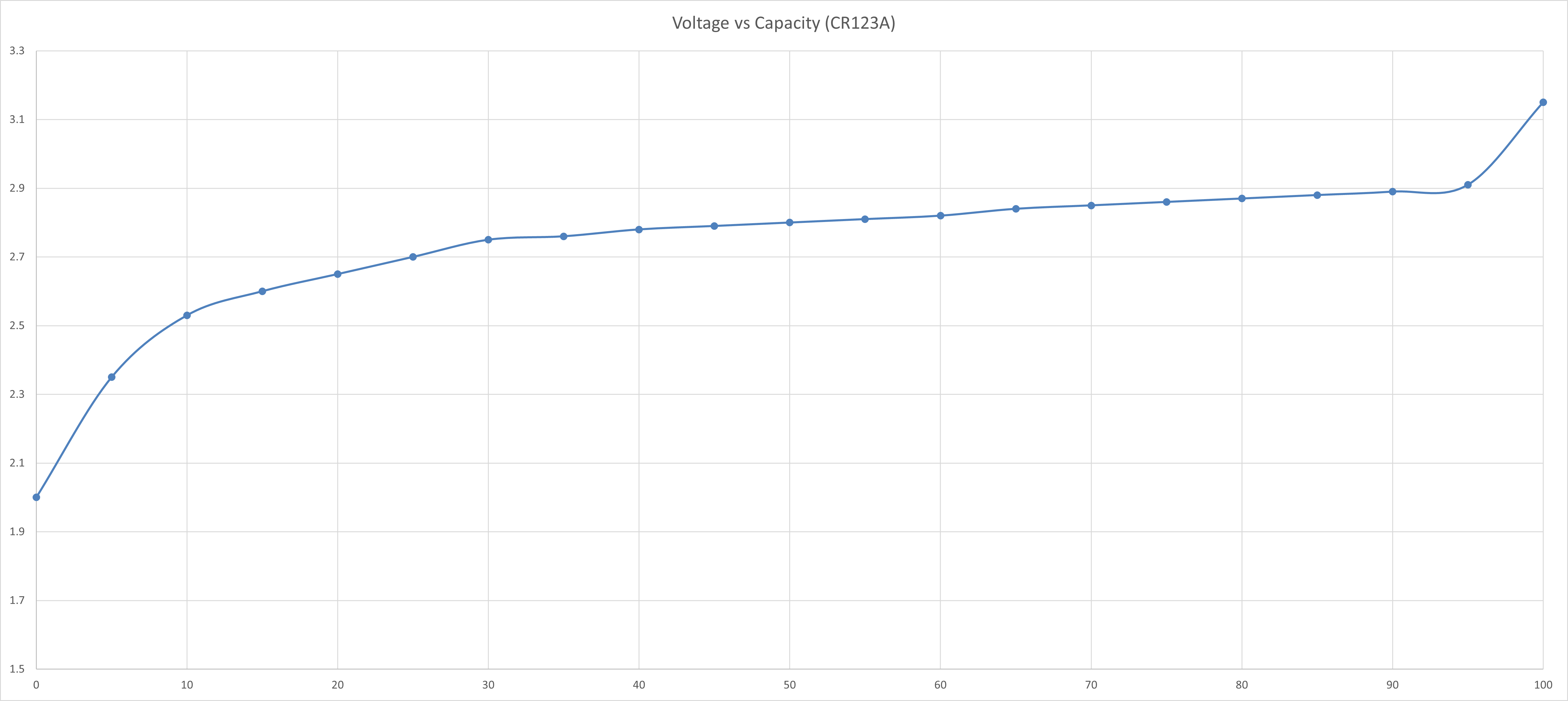

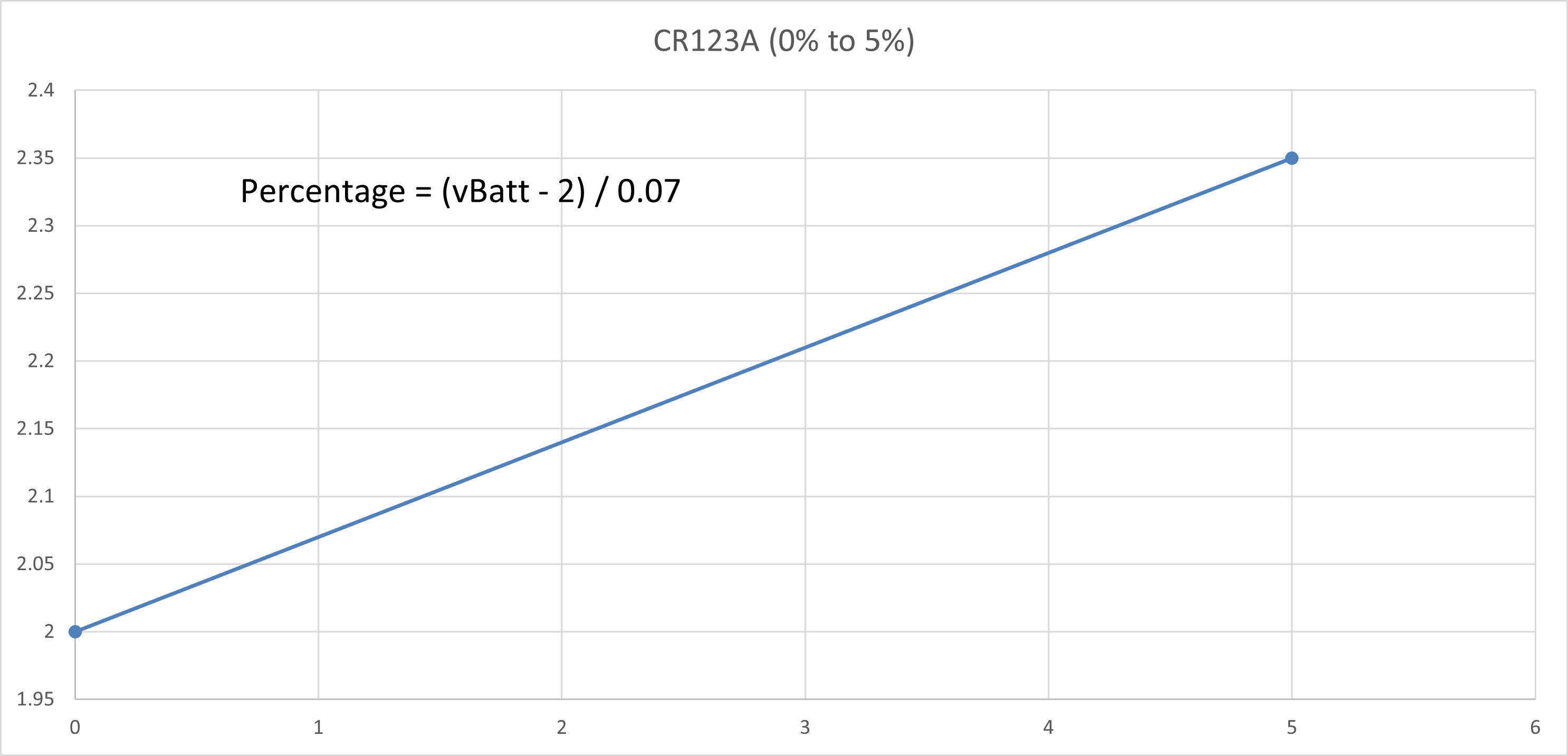

CR123A 3V Non-Rechargeable Lithium Battery

The typical 3V Lithium Battery voltage vs capacity table is shown as follows:

| Capacity | Voltage |

|---|---|

| 100 | 3.15 |

| 95 | 2.91 |

| 90 | 2.89 |

| 85 | 2.88 |

| 80 | 2.87 |

| 75 | 2.86 |

| 70 | 2.85 |

| 65 | 2.84 |

| 60 | 2.82 |

| 55 | 2.81 |

| 50 | 2.80 |

| 45 | 2.79 |

| 40 | 2.78 |

| 35 | 2.76 |

| 30 | 2.75 |

| 25 | 2.70 |

| 20 | 2.65 |

| 15 | 2.60 |

| 10 | 2.53 |

| 5 | 2.35 |

| 0 | 2.00 |

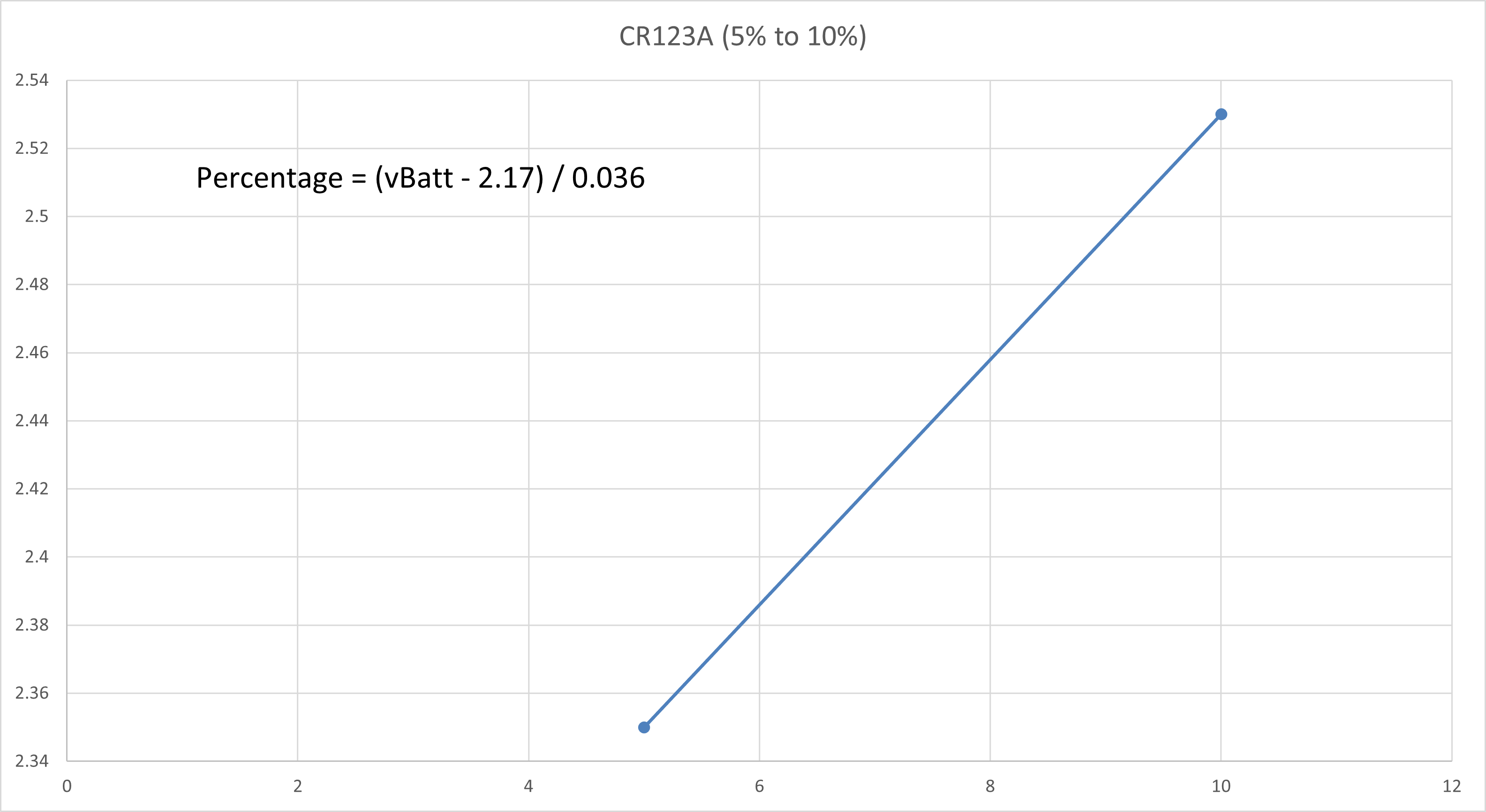

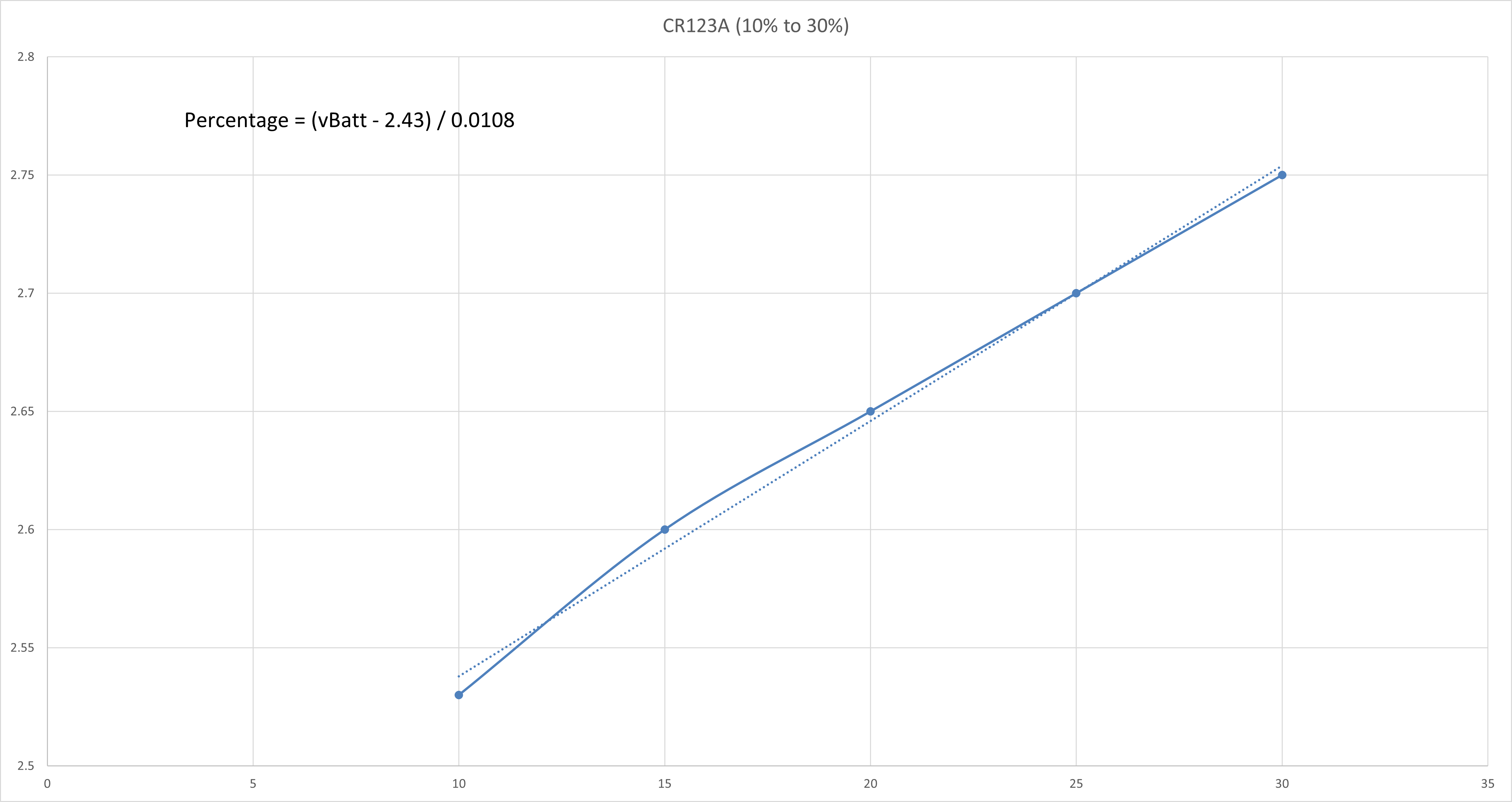

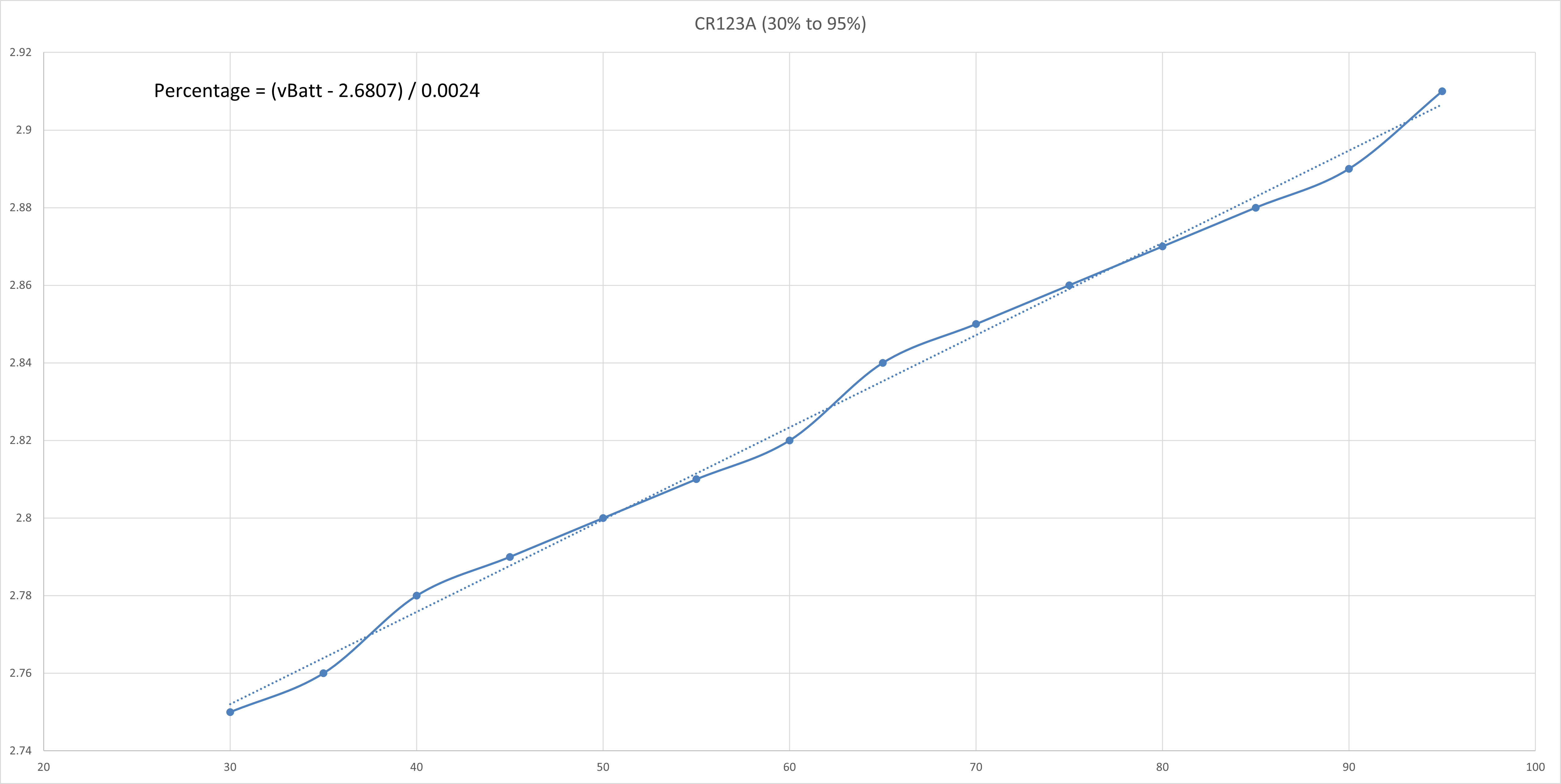

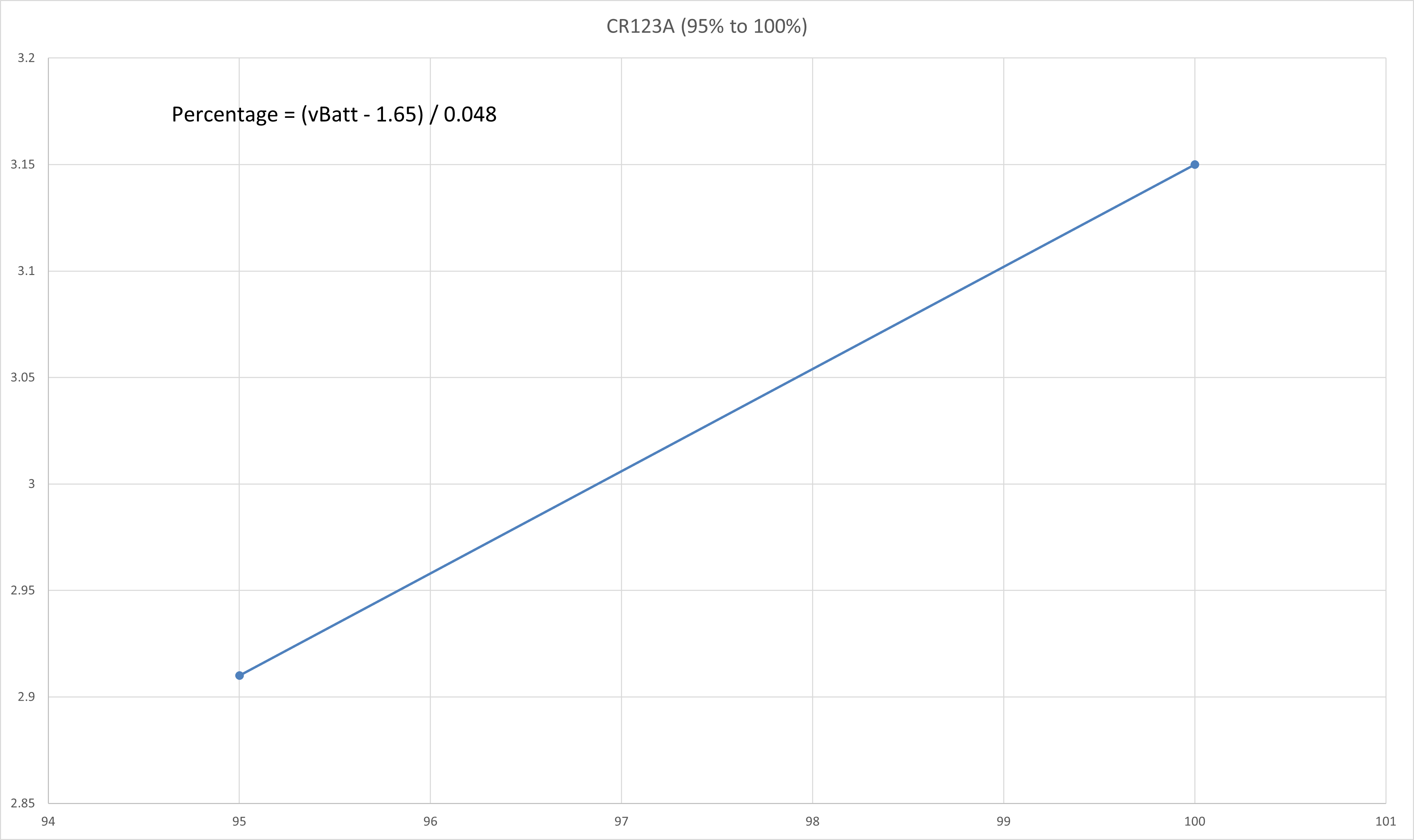

The voltage vs capacity graph is then plotted using Excel and is shown as follows:

The curve is then split into a few regions where each region could be reasonably linearised with a line of best fit. The straight line equation of each linearised region is obtained and the battery percentage value could be calculated correspondingly.

References

- Another RCR123A charge/discharge curve could be found here.

- The charge/discharge curve of the CR123A battery type is obtained from Energizer datasheet and Duracell datasheet.